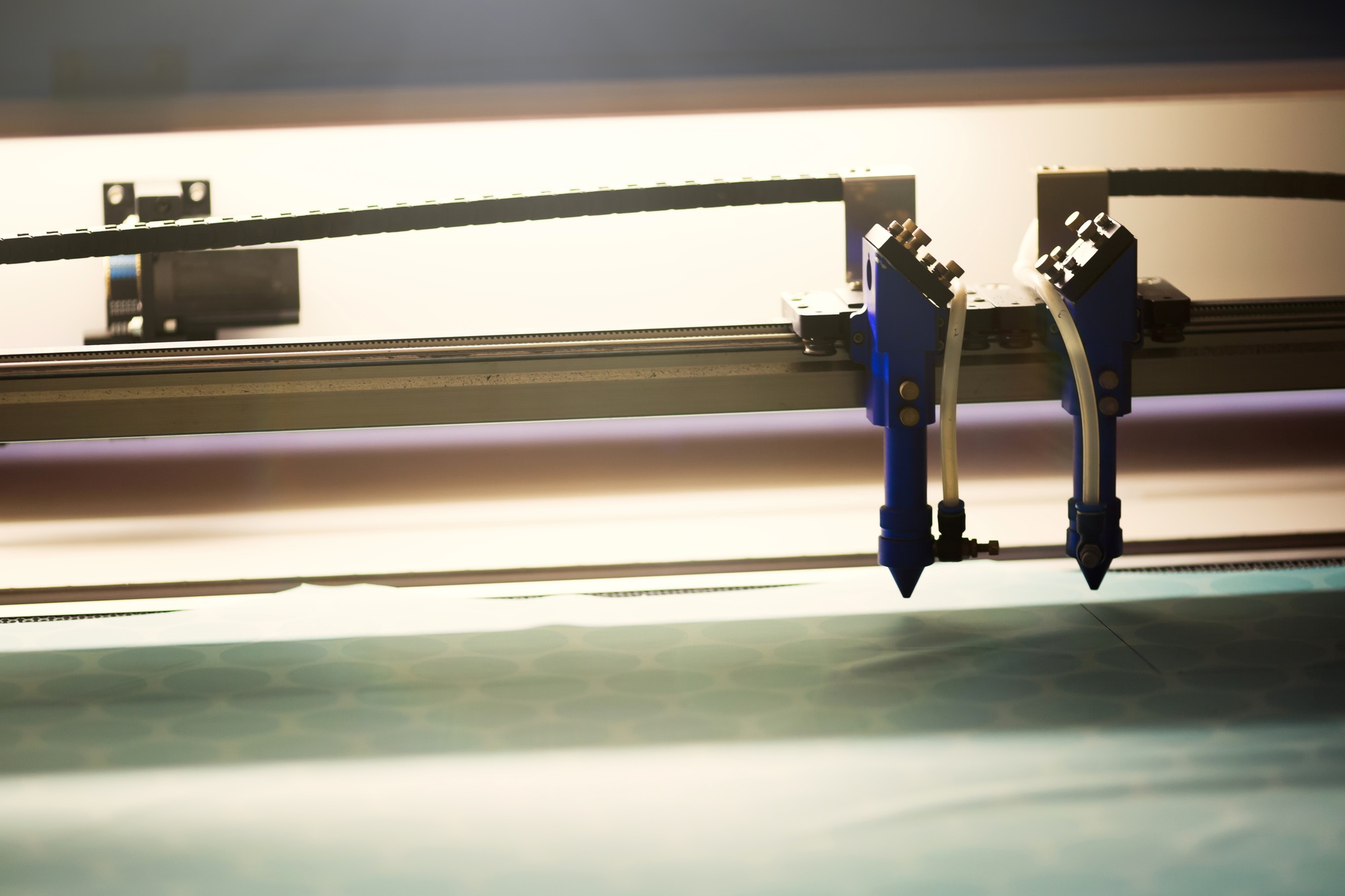

Laser cutting machines are high-tech devices that enable precise and fast cutting of metals, plastics, and other materials. Due to their high energy usage, these machines can reach elevated temperatures, and if not properly cooled, cutting quality may decline, and equipment lifespan may shorten. Chiller systems are among the best solutions to ensure stable and efficient operation of laser cutting machines.

Importance of Heat Management in Laser Cutting

Laser cutting machines use high-powered laser beams to cut materials. During this process, the laser tube, optics, and cutting head are exposed to high temperatures. Without an effective cooling system, the following issues may arise:

- Reduction in laser power, leading to a decline in cutting quality,

- Damage to the laser tube and optical components,

- Decreased overall machine performance and cutting precision,

- Shortened equipment lifespan and increased maintenance costs.

For these reasons, chiller systems that provide precise temperature control are used in laser cutting machines to prevent such problems.

Advantages of Using Chillers

The main benefits of using chillers in laser cutting machines include:

- Maintaining stable laser power to improve cutting quality,

- Preventing overheating of machine components to extend equipment lifespan,

- Ensuring continuous and reliable operation in production,

- Reducing costs by recycling water through a closed-loop system,

- Offering an energy-efficient system to minimize operating expenses.

Chiller Selection and Capacity Determination

When selecting a suitable chiller system for laser cutting machines, the following factors should be considered:

- Laser power (in Watts or kW),

- Machine operating time and workload,

- Cooling fluid temperature tolerance,

- Operating environment temperature and climate conditions,

- Energy efficiency and ease of maintenance.